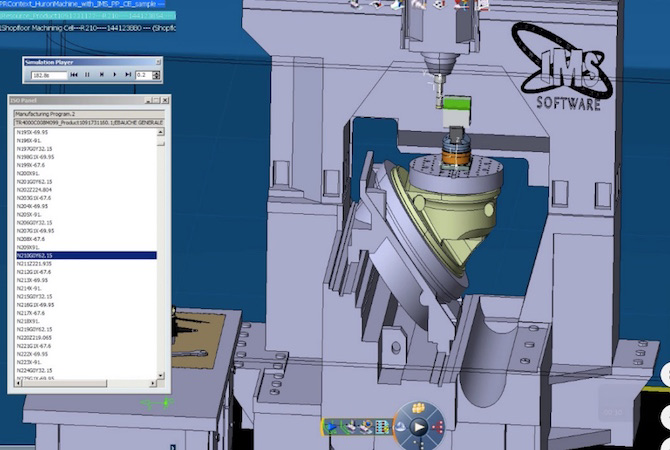

IMSce provides robust controller emulation for all types of CNC controllers on the market today. Full support for controller variables, subprograms, expressions, canned cycles, probing, and more ensures the most accurate and robust simulation available in the industry.

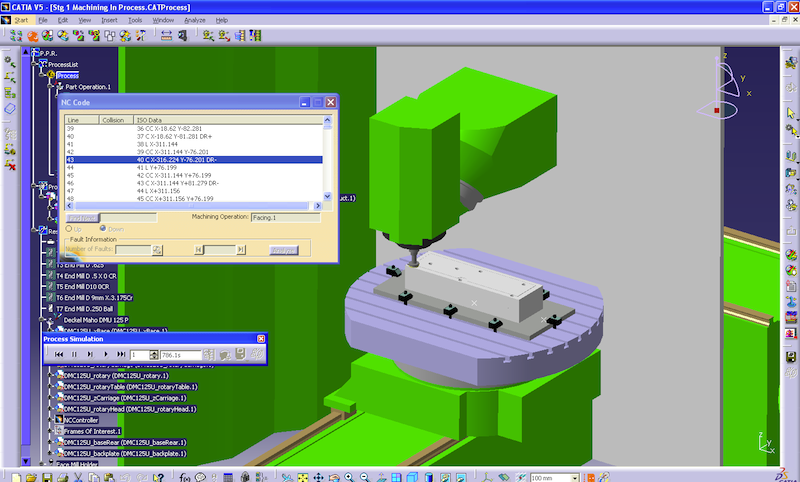

CATIA V5 and V6 from Dassault Systemes provide a unique integrated approach allowing G-code validation without leaving the CAM environment. The IMSce controller emulation capability provides the machine motion while checking for syntax and logic errors and alerting the user when they occur.

Unlike IMS products, most CAM software provides NC verification with material removal and, in some cases, machine simulation. But this normally checks only the toolpath generated by the software. The operations that take place between the CAM system and the machine (postprocessing to convert the toolpath to the correct format; optimization for speeds, feeds, retraction, and reorientation at machine limits; or, simply hand-editing by the operator) can introduce conditions that can be costly if not identified before the part is on the machine.

IMSce solves this problem. Controller emulation provides processing of machine-specific G and M-code, allowing the integrated verification and simulation within CATIA V5 and V6 to check the actual data that will drive the machine, not just the toolpath as generated by the CAM system.